What Is MTBF (Mean Time Between Failure) ?

Summary: MTBF (Mean time between failures) is the predicted running time of a mechanical or electronic system between inherent failures during regular system operation. It is a crucial maintenance measure for the performance, equipment design, reliability, and safety of a hardware product or component.

MTBF can be the average arithmetic time between failures of repairable systems. In contrast, MTTF (mean time to failure) indicates the expected failure time for a non-repairable system. The higher the MTBF is, the longer the system may work before it fails.

Table of Contents

MTBF Calculation

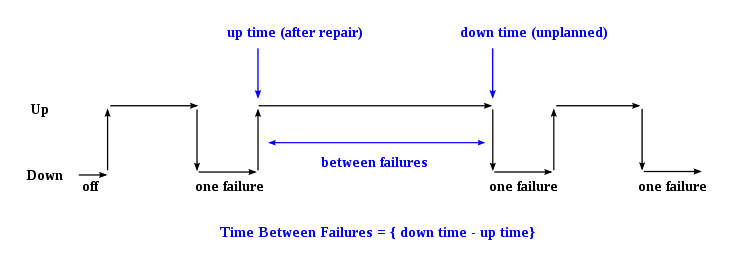

Measured in hours, MTBF helps users understand the reliability and availability of their equipment. It shows the expected time between two failures for a repairable mechanical or electronic system.

For example, three identical systems that start functioning normally at time 0 are working until they all fail. The first system fails after 120 hours, and the second fails after 140 hours and the third after 150 hours. Then the MTBF of the repairable systems is 136.667 hours, the average time of the three failures.

MTBF is calculated by dividing the total operating hours of the equipment by the number of failures that occurred during the same period.

MTBF = Total uptime / Time of breakdowns

Application

MTBF, as a maintenance indicator, shows the duration of the equipment’s non-disturbing operation. It is intuitively related to the availability ( uptime) of the device.

MTBF applies only to repairable systems or items. Its value prediction is a vital factor in product development.

Used in manufacturing processes, it can plan for unexpected events that require repairing critical equipment. Understanding this data offers insights into the right decisions for the plant.

Design engineers and Reliability engineers use reliability software to calculate a product’s MTBF based on a variety of methods and standards.

MTBF vs MTTF vs MTTR

These are three items related to data center management that apply to hardware.

MTBF — Mean Time Between Failure

- MTBF is a reliability term typically used to specify the overall failure rate for products and equipment.

- It is used for both repairable and replaceable/non-repairable equipment and products.

- MTBF is more critical to integrators and industry than to consumers.

- It is the total operational uptime between failures divided by the number of crashes.

- Multiple data points would be required to get a reliable and accurate MTBF.

MTTF — Mean Time To Failure

- MTTF is an essential measure of reliability for non-repairable items or systems.

- It is used to predict the failure rate of a product, which is similar to MTBF. But can only be used for replaceable or non-repairable equipment and products.

- Only a single data point for each failed part is required to get the MTTF.

MTTR — Mean Time To Repair

- MTTR is the needed time to repair a failed hardware, which means to replace a failed hardware part.

- MTBF and MTTF measure the time related to failures, but MTTR measures how long it takes for the failed product to run again.

- It is can only be applied to MTBF predictions because it implies that the product will be repaired.

- Unrepaired items, which may have MTTF numbers, will not have MTTR predictions – as they will be replaced rather than repaired.

Improve MTBF

Increasing MTBF increases the uptime of the device. Track the MTBF for each piece of equipment, especially those that require continuous operation, enabling maintenance teams to schedule maintenance activities effectively.

Some steps can be applied to improve MTBF:

- The first step is to make sure that the collected data is accurate. Various maintenance tools can ensure the accuracy of the recorded data.

- The next step is to use it to perform preventive maintenance in collecting data proactively.

Boost your Business with MTBF

Failure is more than just a matter for the maintenance department. Tracking the MTBF can help users make reliable data-driven decisions and maximize maintenance capabilities and get the most out of their processes.

Previous Article

Learn How To Reuse Watermark Photo Or Video! Summary: MTBF (Mean time between failures) is the predicted running time of a mechanical or electronic system between inherent failures...Next Article

What is Hard Disk Drive (HDD)? Summary: MTBF (Mean time between failures) is the predicted running time of a mechanical or electronic system between inherent failures...

About Bitwar Data Recovery

3 Steps to get back 500+ kinds of deleted, formatted or lost documents, photos, videos, audios, archive files from various data loss scenarios.

Learn More